MODULAR HOUSE, ATELIER MYCC, SPAIN

Fact Sheet

Product: Viroc Grey

Applied on: Roofs and facades

Architecture: Carmina Casajuana, Beatriz G.Casares and Marcos González, Atelier MYCC

Photography: FG + SG

Location: Spain

Built in three months and assembled in three days, this vacation house located in the Galician municipality of Cedeira is a good example of the many possibilities that modular construction, up to now associated with catalogue houses, offers today.

The program demanded by the client, along with the unique site of the house and modulation and transportation needs of prefabricated construction, inspired the design of this house built by the young Madrid studio MYCC, formed by Carmina Casajuana, Beatriz G. Casares and Marcos González.

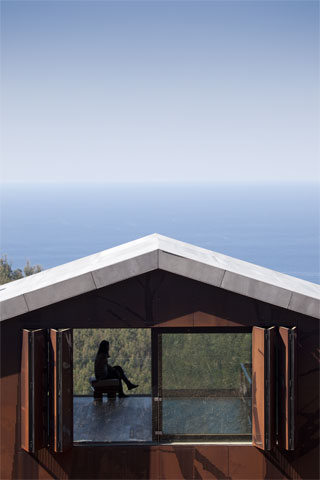

The house is located on a steep slope, in a remote location in the northeast corner of the Iberian Peninsula, an area dominated by the imposing presence of the ocean and the slender forest of eucalyptus trees surrounding it. The terrain is surrounded by harvest fields, family farms and pitched roof houses. This image, protected by the area’s building codes, determined the geometry of the house that, simplified up to the point of evoking the basic house, was conceived as an autonomous piece that sits as a landscape observer and that speaks, with new terms, about the traditional language of the place.

The volume was wrapped with two materials with the purpose of setting up a dialogue with the landscape.

The roof and the side facades were covered with Viroc due to “it’s great strength efficiency in spite of being light and, therefore, is easy to maintain and move”.

According to Beatriz, Viroc was also chosen because of its concrete appearance and its “naturalness of being made of wood and not plastic”.

The two main facades of the house were clad with perforated corten trays following the schematized image of a forest silhouette, recreating the image of the surrounding vegetation.

After an assembly trial in the factory, and after making sure that everything fit in properly, the different modules and trusses of the building were taken apart to be packed and moved in trailers the whole 700 kilometers separating the factory from the remote seaside site where it was to be installed. All the parts were put together again on the designated site in just three days, and the finishing touch-ups were done in the following two weeks.

The end result is a high-quality product, designed with high standards of energy efficiency and sustainability.

Further information:

mycc.es

archdaily.com/70220/prefabricated-nature-mycc